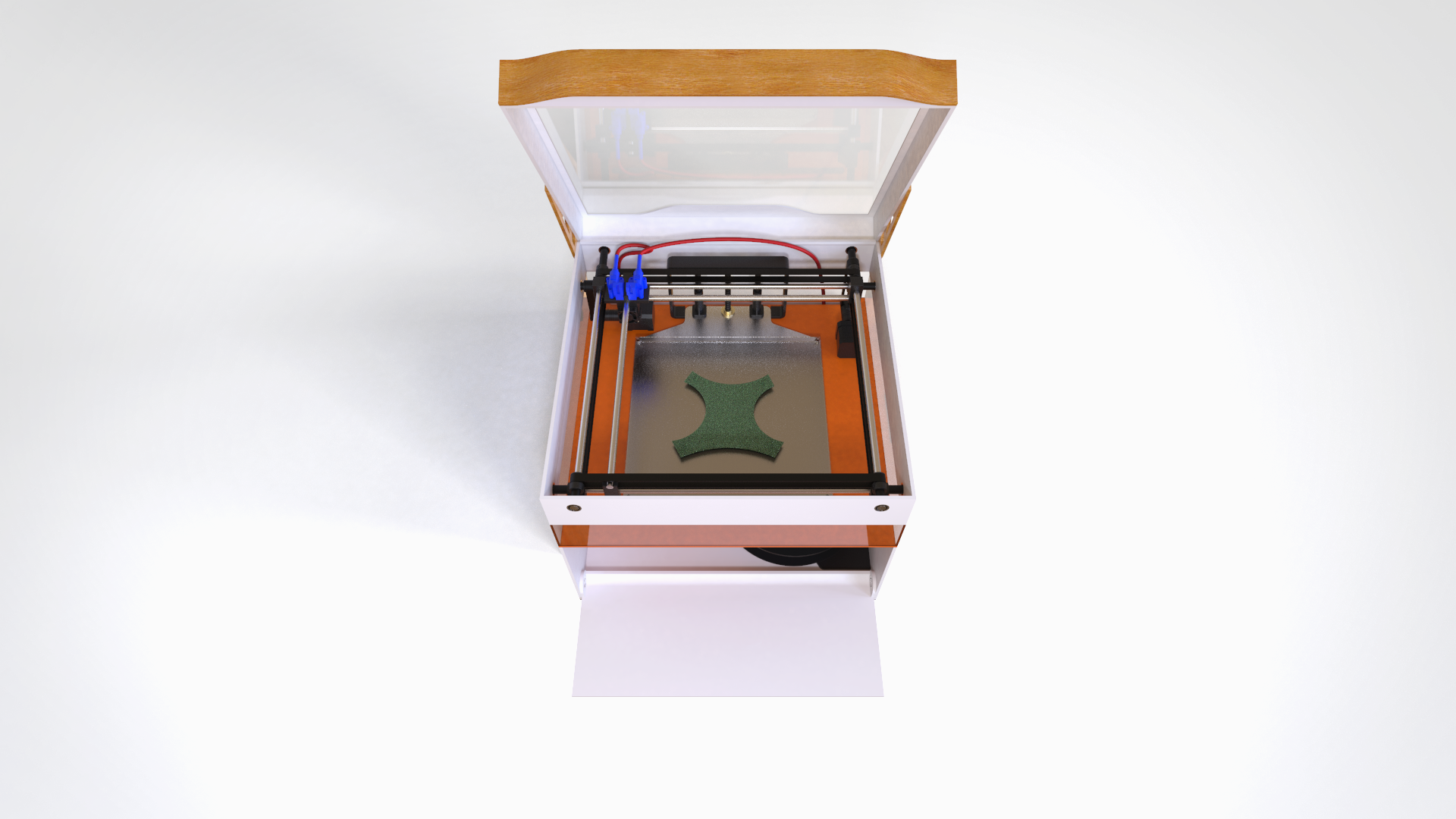

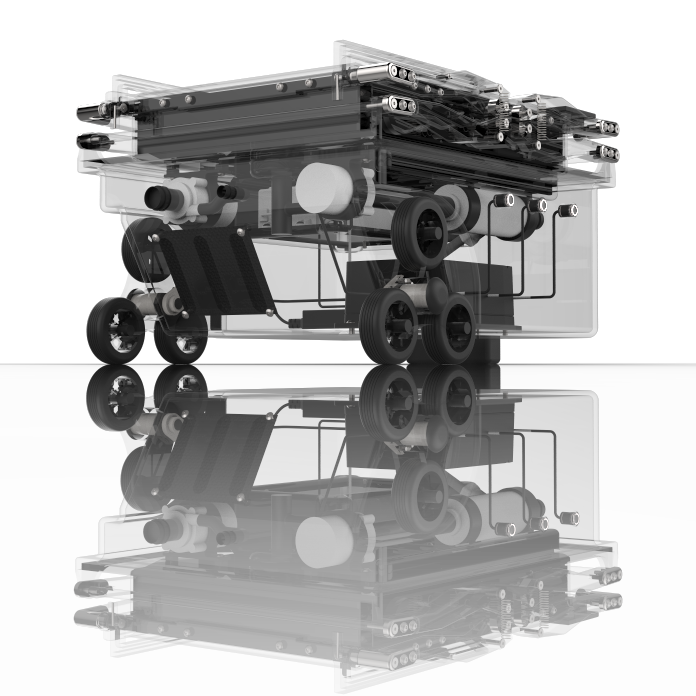

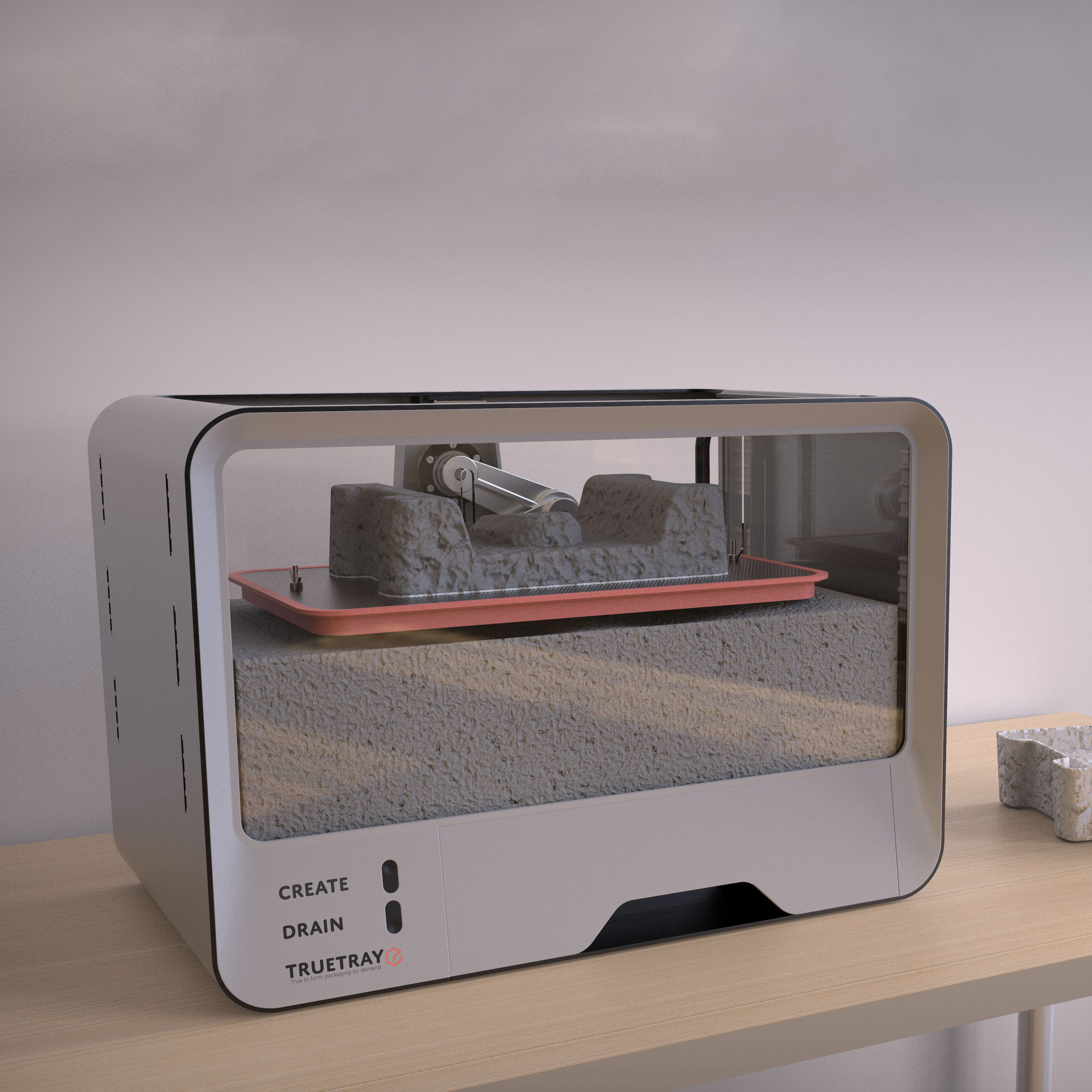

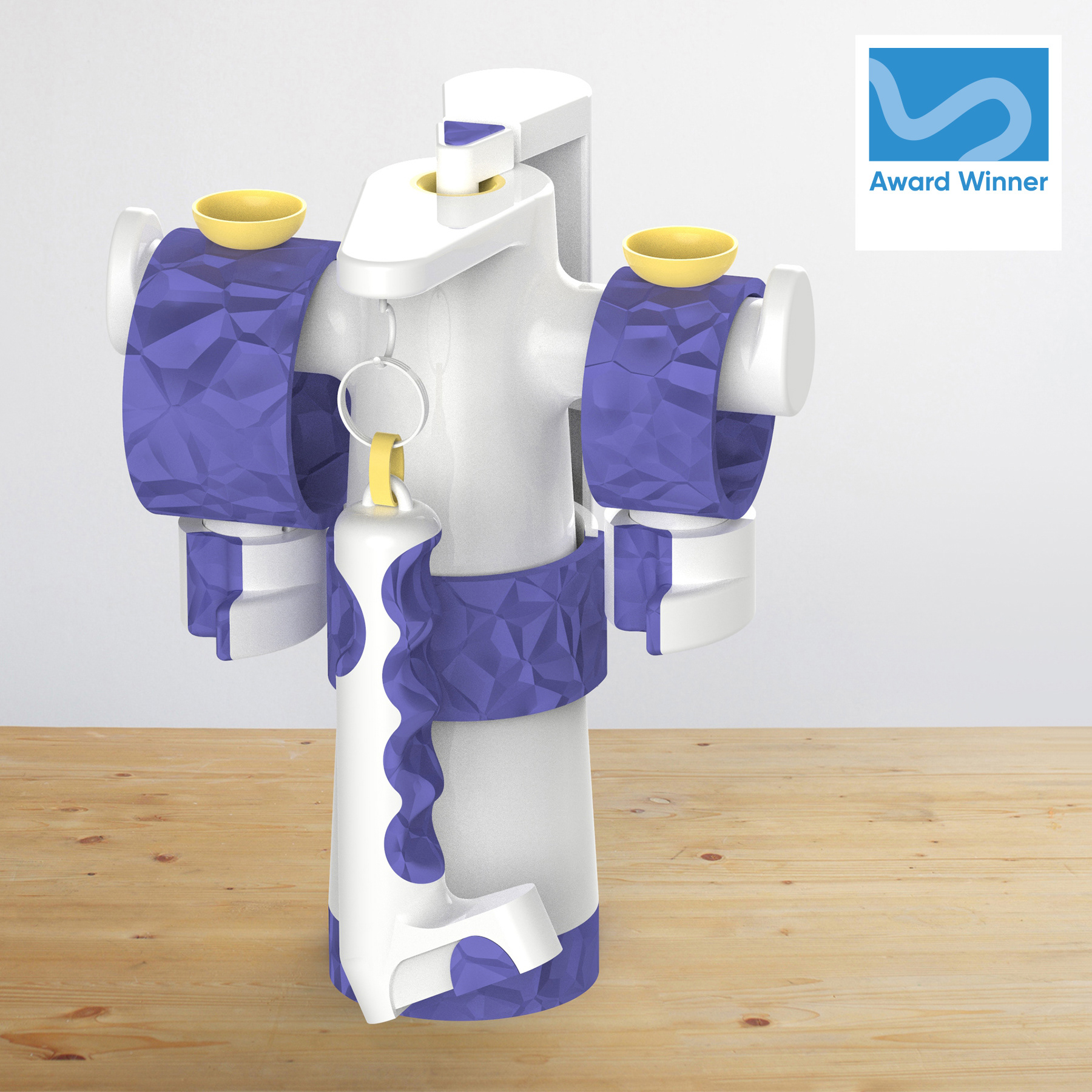

The project comprises two main parts, a bespoke 3D printing appliance and a modular footwear component. The printing appliance has been designed for operation in Timberland’s flagship store. It includes integration of relevant branding and several functional aspects that differentiate it from other FDM printer appliances. Its dual extruder has been optimised for fast yet accurate material deposition, carried out within an airtight enclosure, which shields the user from particulates produced during operation. The flexible footwear component attaches to eyelets on Timberland’s six-inch boot via snap-fits located on its underside. Each printed component is personalised to accommodate the customer’s varying instep height, which increases both comfort and quality of fit. The printer uses a fully compostable filament, ensuring a circular life cycle and reducing the product’s overall environmental impact.

A collaborative project with Timberland LLC

Process Photos