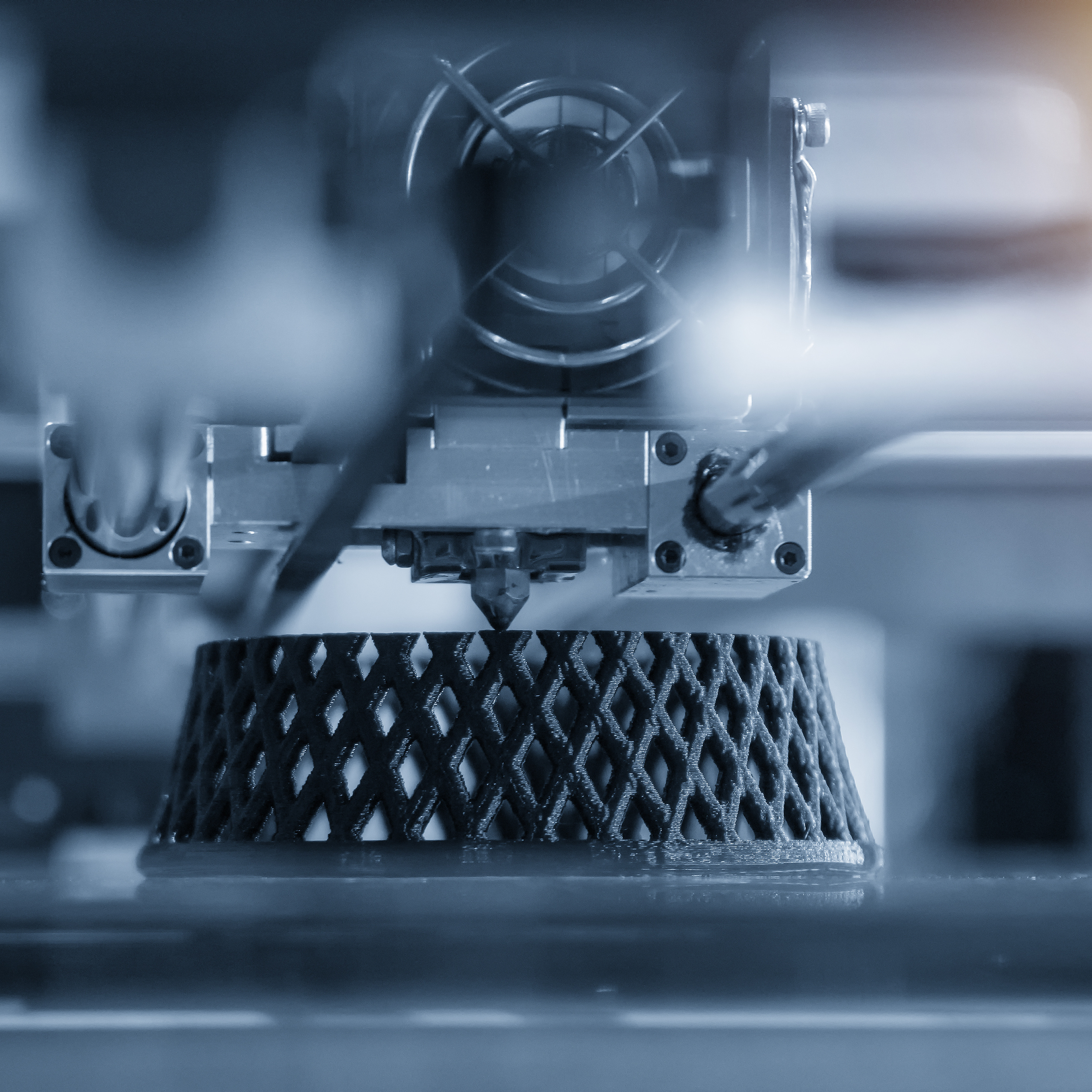

4D Printing (4DP) is defined as the use of Additive Manufacturing (AM) to produce stimuli-responsive parts that can transform from one form to another when subject to an external stimulus, without electro-mechanical devices. We also define Functionally Graded Additive Manufacturing (FGAM) as a layer-by-layer fabrication process achieved by intentionally modifying the process parameters and gradationally varying the spatial deposition of material organization within a single component to meet an intended function.

This research examines the state of the art of 4D Printing (4DP) and Functionally Graded Additive Manufacturing (FGAM), clarifying their differences and determining the most suitable AM process for the creation of shape-changing thermo- responsive textiles. The key research areas include proposing a framework to select commercially available shape memory polymers suitable for 4D Printing; establishing a methodology for direct material extrusion onto textile substrates to create polymer-textile composites; and investigating key build and design parameters that will have the greatest influence over geometrical deformation of the textile.