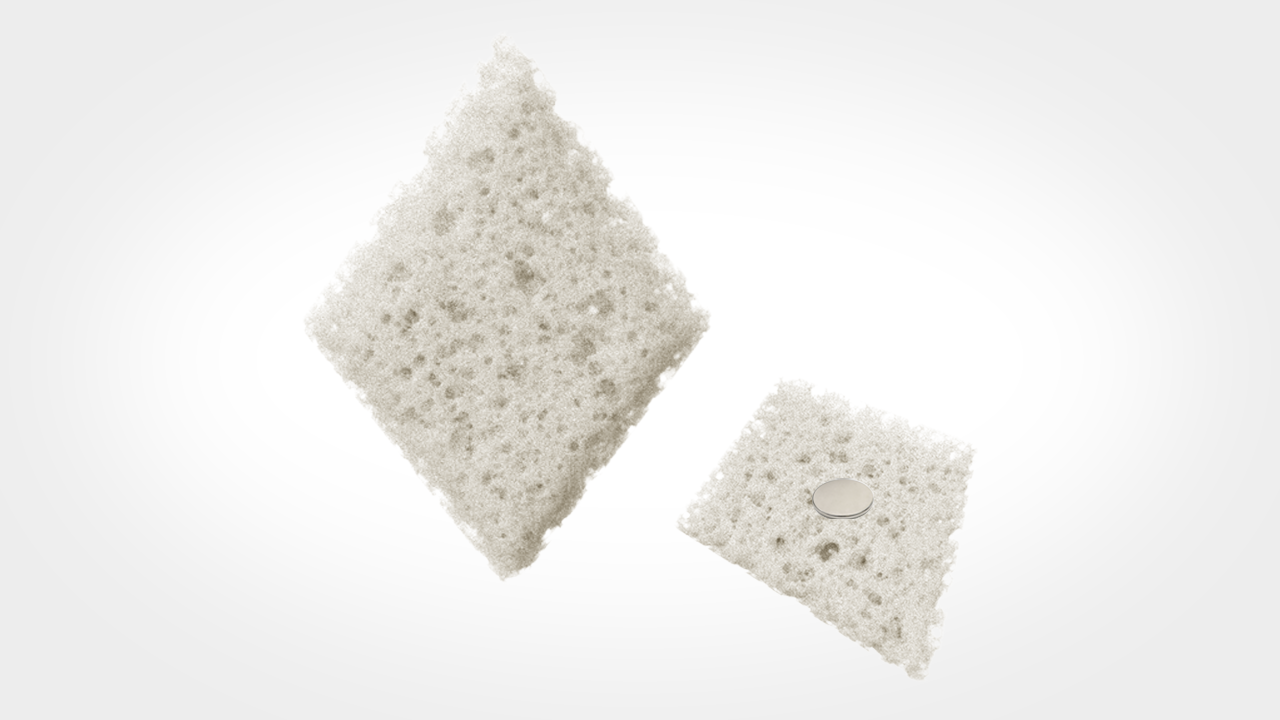

Our planet is suffering under the consequences of unsustainable production. Many materials used in industry are exploiting the earth’s resources, polluting the environment, using a lot of energy or releasing greenhouse emissions during their product life cycle. Current unsustainable sound insulation products are made of, for example, PU foam which will become an increasing environmental problem. The opportunity arises to create modular panels made of a local, sustainable and compostable sound absorbing material with a small environmental footprint. The material is made of mainly mycelium and carrot peeling waste to absorb sound within music recording and rehearsal rooms. Circular economy models like this encourage inward investment, drive innovation, protect natural capital as well as minimise the environmental impacts of production, use and disposal.

Process Photos