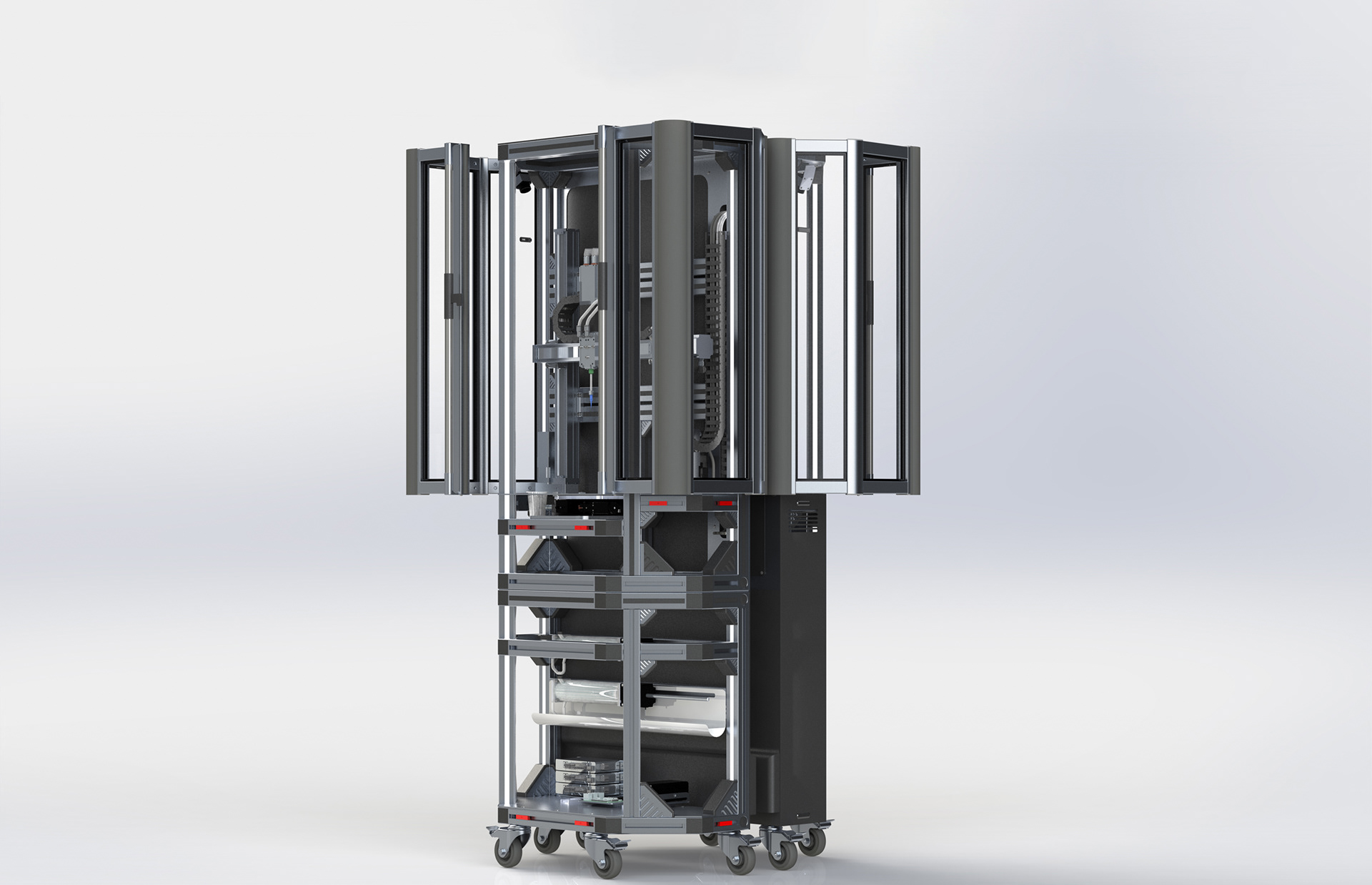

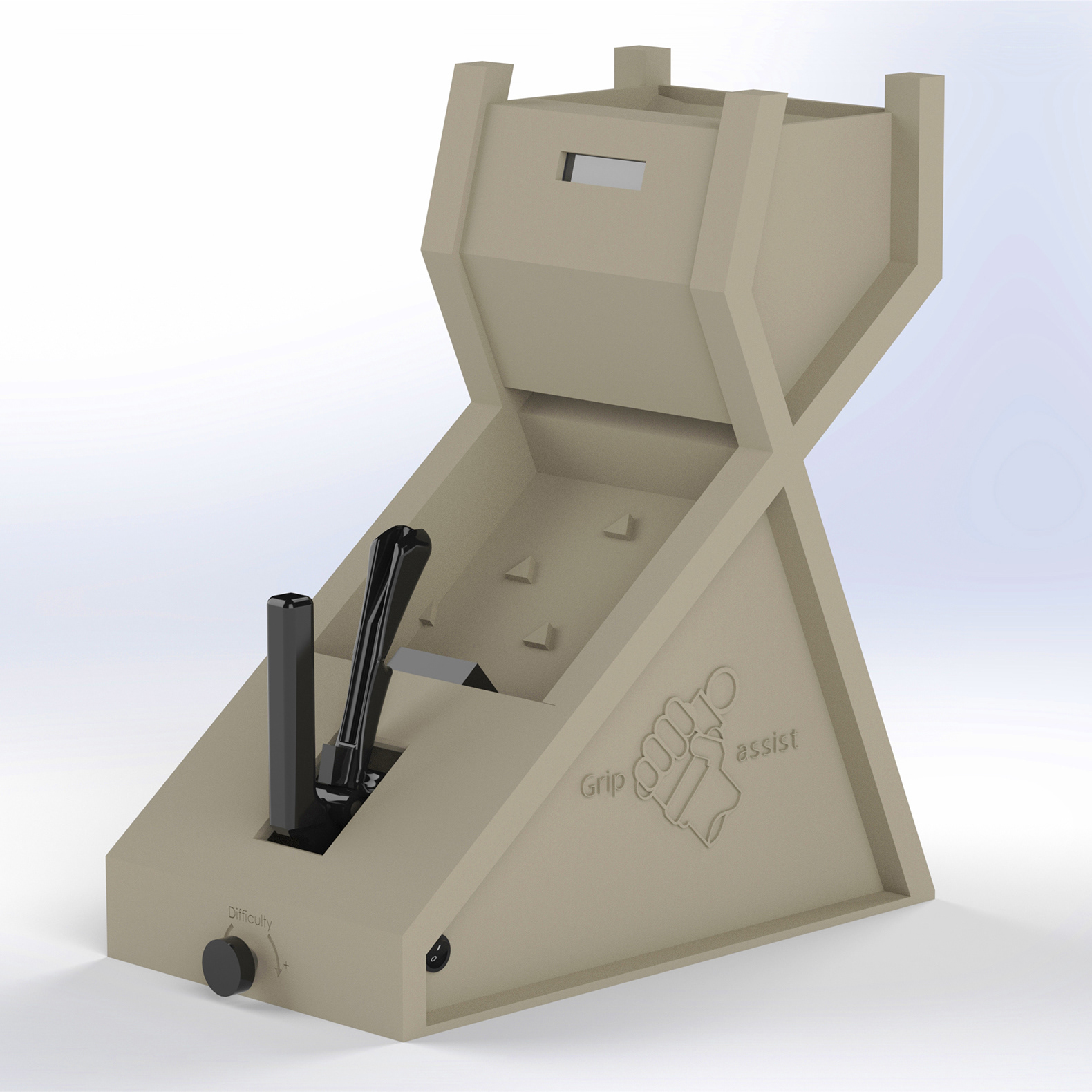

Prosthetics for Lower Limb Amputees (LLA) have been neglected regarding their material and function performance. Current manufacturing techniques are limiting the progression of these products and, therefore, leading to lower-performance components. The use of Liquid Additive Manufacturing along with Polar Architecture produces products with significant benefits to product longevity, performance and reduction in manufacturing time. The final deliverable is a solution for the 3D manufacturing of lower limb prosthetic sockets for a lower cost, with a massive reduction in time, and significantly greater customisability with a greater degree of finetuning. This leads to a prosthetic socket for a lower limb amputee that is functional and stable enough to compete with current market sockets, offering a new solution to a stagnant market.

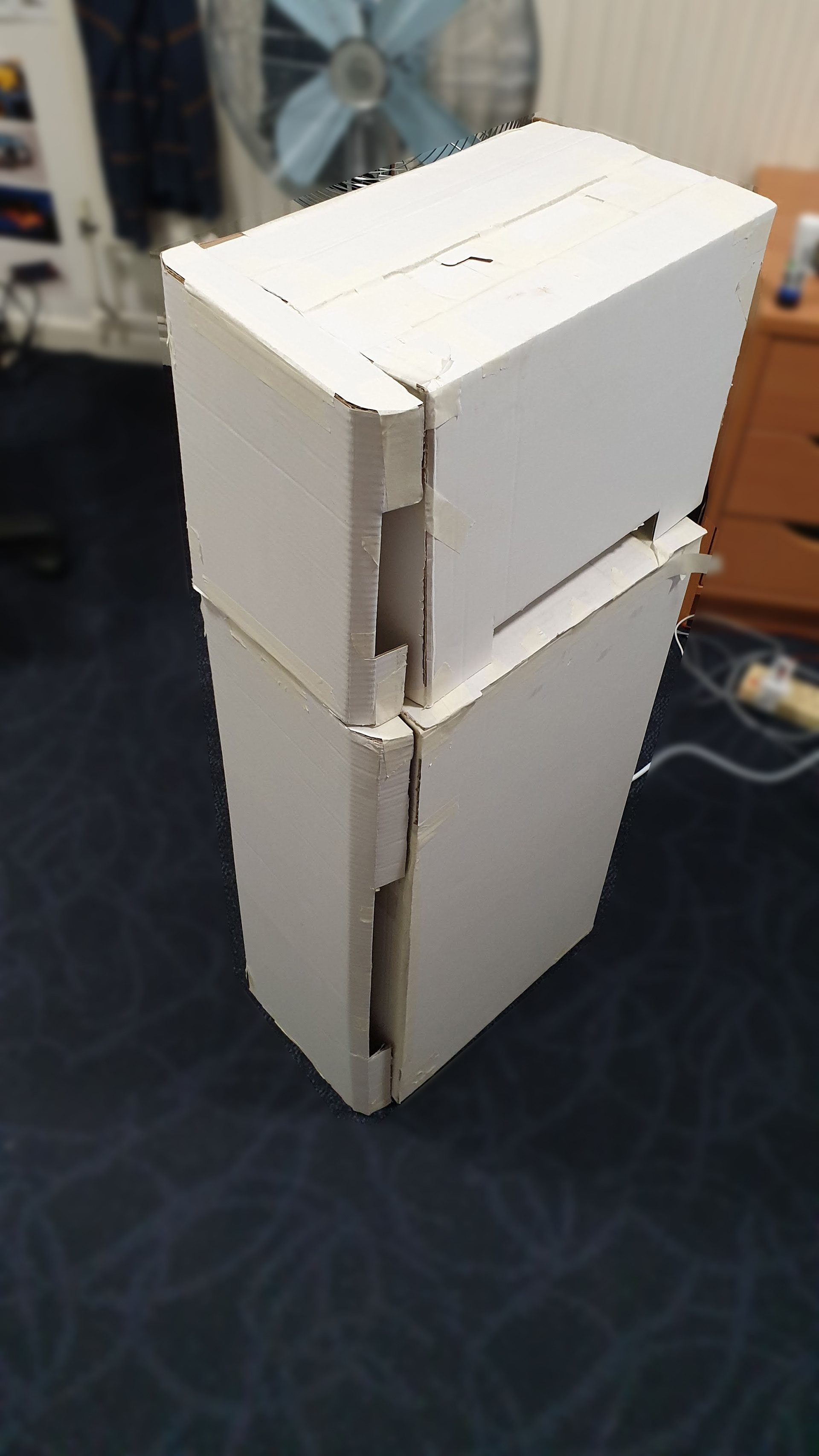

Process Photos